Compact Small Size Electric Resistance Dental Furnace for Heating Treatment

KSL-1700C denal furnace is widely used in zirconia sintering in the denture processing industry, it can also be used for sintering and annealing high

KSL-1700C denal furnace is widely used in zirconia sintering in the denture processing industry, it can also be used for sintering and annealing high

temperature materials in the powder metallurgy industry. it is the most ideal product for high temperature sintering and metal annealing in universities,

research institutes, industrial and mining enterprises.

Product advantage:

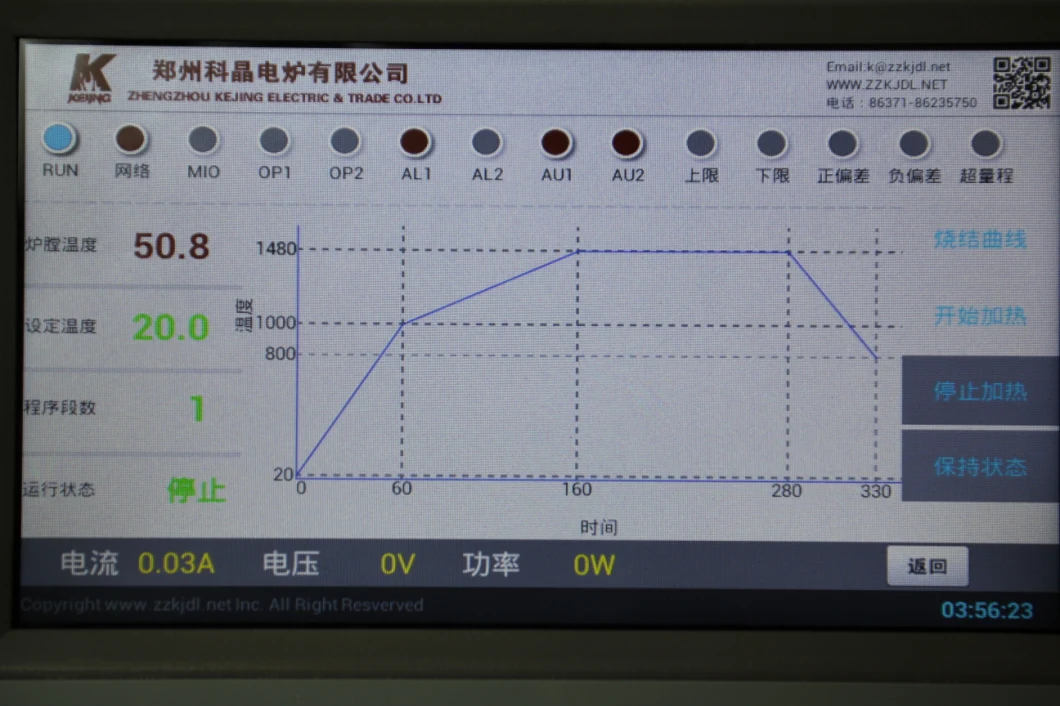

Touch screen control system makes the device's control more convenient and quick and humanization.

Furnace with round structure, the heating elements uniform distribution on the circumference, the temperature field is more uniform and reasonable.

The furnace body is loaded with an automatic lifting structure, which is beneficial to safely picking and placing the sintered pattern, especially for the

high temperature sinter sintering of the zirconia denture crown, with good consistency and high permeability.

All of the dental furnace products also can accept customized.

Product specification:

| Model | Chamber Size | Max temperature | Rated voltage | Rated power(kw) | Temperature control accuracy | External size | Max temperature rate | Net wight | |||||

| Diameter | Height | Length | width | Height | |||||||||

| TSL-1200X | 120 | 200 | 1200 | AC:220V 50/60Hz | 1.5 | +/-1 ºC | 550 | 430 | 860 | 15 | 65 | ||

| TSL-1500X | 120 | 200 | 1400 | AC:220V 50/60Hz | 1.6 | +/-1 ºC | 550 | 430 | 860 | 15 | 65 | ||

| TSL-1700X | 120 | 200 | 1650 | AC:220V 50/60Hz | 2 | +/-1 ºC | 550 | 430 | 860 | 25 | 76 | ||

| TSL-1800X | 120 | 200 | 1700 | AC:220V 50/60Hz | 2.2 | +/-1 ºC | 550 | 430 | 860 | 10 | 76 | ||

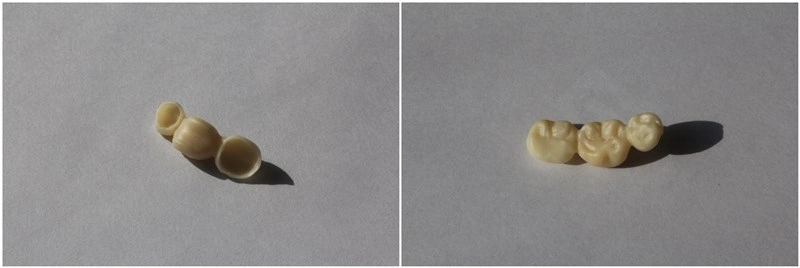

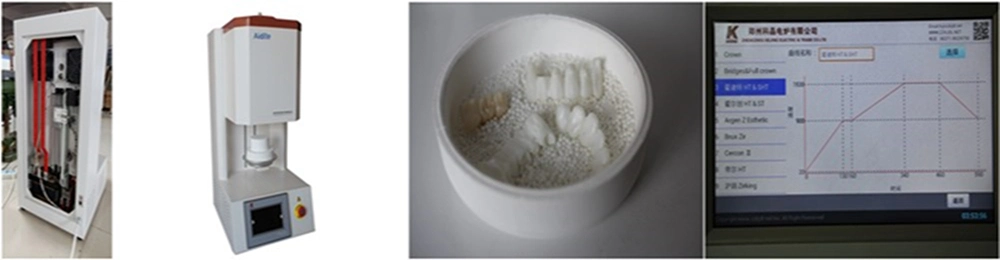

Reference pictures of the dental zirconia sintering furnace:

Feature

1. PID automatic control via SCR (Silicon Controlled Rectifier) power control, e. g. current limiting phase angle fired the resistor with 51 programmable segments.

2.Touch Screen

3. zirconia sintering products