Friction resistant ceramic ball

There are many kinds of ceramic balls. There are several kinds of our products:

[suitable equipment] grinding medium for ball mill, stirring mill, stripper, polishing machine and sand mill (AI sand mill).

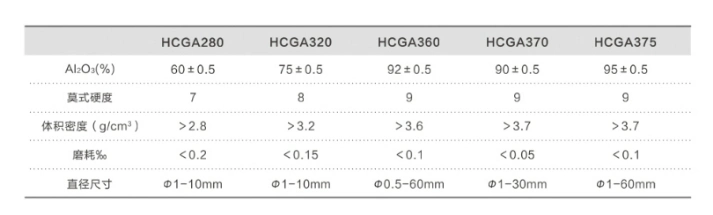

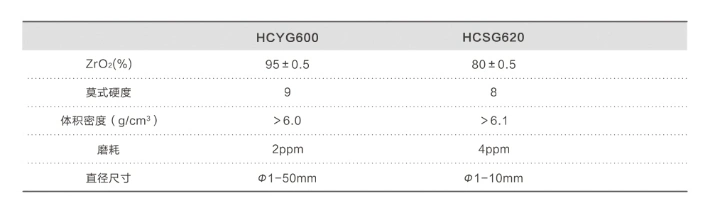

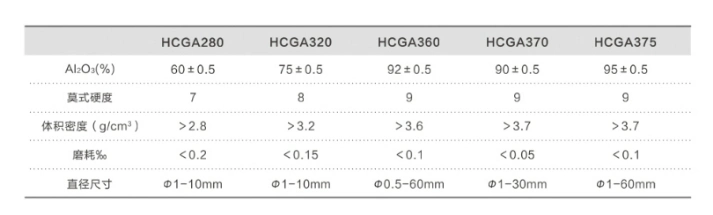

1,Alumina ball:φ0.5-60mm

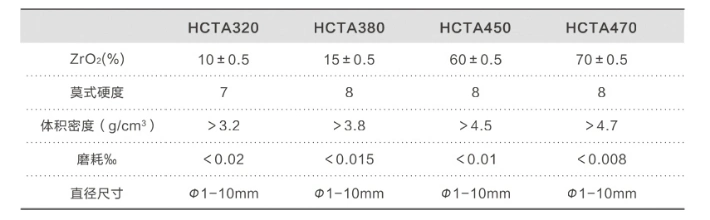

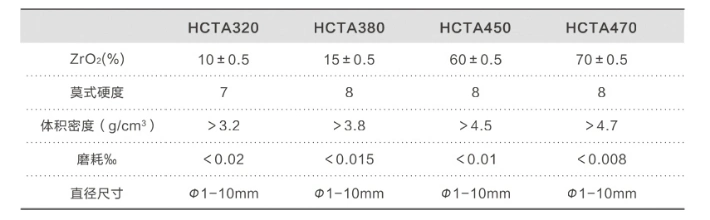

2,Zirconium aluminum composite ball:φ1-10mm

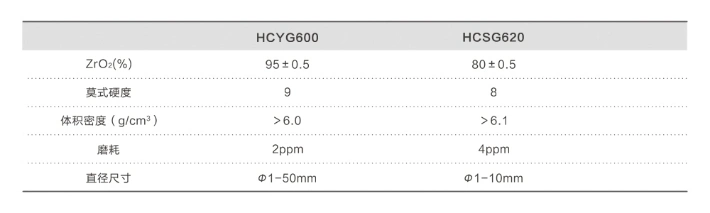

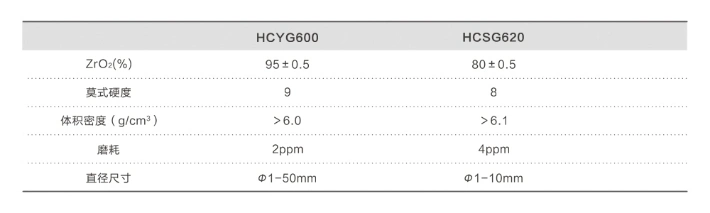

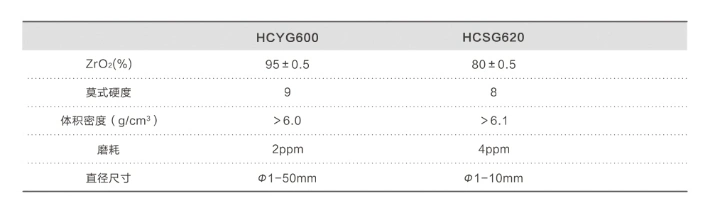

3,Yttrium stabilized zirconia ball:φ1-50mm

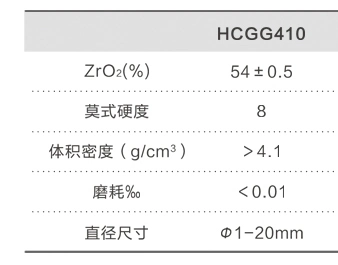

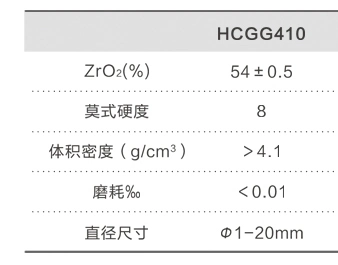

4,Zirconium silicate ball: φ1-20mm

5,Cerium stabilized zirconia ball: φ1-10mm

[suitable equipment] grinding medium for ball mill, stirring mill, stripper, polishing machine and sand mill (AI sand mill).

[product features] low wear, high hardness, corrosion resistance, impact resistance, economical and practical.

It is mainly used in non-ferrous metal ore, industrial ceramic powder material, non-metallic powder material, titanium dioxide, paper making, coating, ink, other powder materials and other fields; it is suitable for grinding medium of various equipment such as argyi sand mill, ball mill, stirring mill, stripper, polishing machine and sanding machine.

1, High abradability: the wear resistance of the scientific formula ceramic ball is 2-5 times higher than that of the general material.

2, Good fluidity: thanks to the advanced preparation technology, the surface of the ball is smooth, and the self-lubricating performance of the ceramics is outstanding. The scientific separation process ensures the optimal roundness and low wear in grinding conditions.

3, Impact resistance and wear resistance: toughened ceramics have good toughness at high temperature, which can be easily handled even in equipment with high working strength.

The quality has reached the international level through the British grinding solutions laboratory test, and the overall grinding medium quality is not lower than that of Marco Belgium, Sano Korea and Saint Gobain, France. The quality of zirconium silicate grinding medium and ZTA grinding medium has exceeded that of foreign products in the same industry, with higher cost performance.

There are many kinds of ceramic balls. There are several kinds of our products:

[suitable equipment] grinding medium for ball mill, stirring mill, stripper, polishing machine and sand mill (AI sand mill).

1,Alumina ball:φ0.5-60mm

2,Zirconium aluminum composite ball:φ1-10mm

3,Yttrium stabilized zirconia ball:φ1-50mm

4,Zirconium silicate ball: φ1-20mm

5,Cerium stabilized zirconia ball: φ1-10mm

[suitable equipment] grinding medium for ball mill, stirring mill, stripper, polishing machine and sand mill (AI sand mill).

[product features] low wear, high hardness, corrosion resistance, impact resistance, economical and practical.

It is mainly used in non-ferrous metal ore, industrial ceramic powder material, non-metallic powder material, titanium dioxide, paper making, coating, ink, other powder materials and other fields; it is suitable for grinding medium of various equipment such as argyi sand mill, ball mill, stirring mill, stripper, polishing machine and sanding machine.

1, High abradability: the wear resistance of the scientific formula ceramic ball is 2-5 times higher than that of the general material.

2, Good fluidity: thanks to the advanced preparation technology, the surface of the ball is smooth, and the self-lubricating performance of the ceramics is outstanding. The scientific separation process ensures the optimal roundness and low wear in grinding conditions.

3, Impact resistance and wear resistance: toughened ceramics have good toughness at high temperature, which can be easily handled even in equipment with high working strength.

The quality has reached the international level through the British grinding solutions laboratory test, and the overall grinding medium quality is not lower than that of Marco Belgium, Sano Korea and Saint Gobain, France. The quality of zirconium silicate grinding medium and ZTA grinding medium has exceeded that of foreign products in the same industry, with higher cost performance.